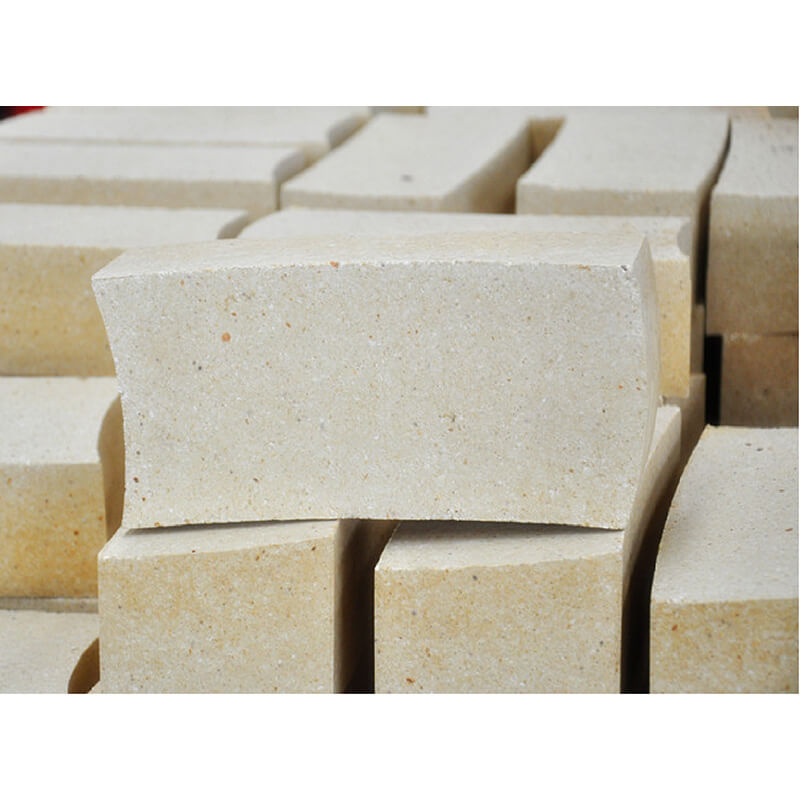

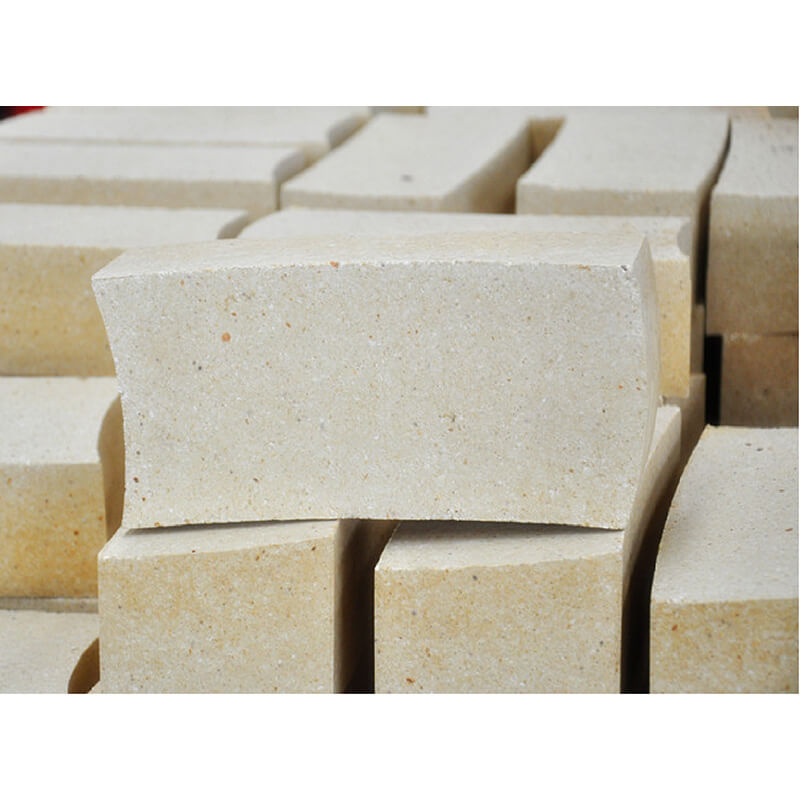

Product Features:

1. Long service life, with more clinker clay bricks increased by 210%

2. From the reduction of unit treatment consumption, also shows the superiority of high aluminum arc brick. And the reduction of unit consumption can explain the corresponding reduction of non-metallic inclusions in molten steel.

3. After inspecting the section of the high alumina brick after its destruction, the corrosion resistance of the slag and molten steel is better than that of the multi-clinker clay brick.

4. Due to the roundness at one end of the high-aluminum curved brick, it can be used when laying bricks. Move back and forth to adjust the roundness, so it is convenient to build refractory bricks, and the brick gap can generally reach 1 mm.

5. The vertical joints of high-aluminum curved bricks are smaller, which is 70% less than the straight joints of standard refractory bricks so that the erosion effect of the molten iron layer moving up and down into the brick joints is corrected.

6. Due to the improvement of the quality of refractory bricks, the thickness of the lining bricks can be reduced, and the capacity of the steel drum is correspondingly increased.

7. Due to the long service life and convenient bricklaying, the labor for building steel drums behind the furnace is reduced, and the utilization rate of steel drums is increased.

Product Parameters:

| Ventilated high alumina brick |

|

project |

index |

| LZ-75 |

LZ-65 |

LZ-55 |

| AL²O³ |

≥75 |

≥65 |

≥55 |

| Refractoriness ℃ |

≥1790 |

≥1770 |

| Starting temperature of load softening ℃ (0.2MPa) |

≥1520 |

≥1500 |

≥1470 |

| Reburning line changes(1500℃*2h)% |

+0.1,-0.4 |

| Apparent porosity |

≤23 |

≤22 |

| Compressive strength at room temperature |

≥53.9 |

≥49.0 |

≥44.1 |

Application Range And After-Sales Service (Application And After-Sales Service):

Application background:

1) Tracking of kilns in cement and other building materials industries;

2) Furnace lining stories in petrochemical, metallurgy, ceramics, and glass industries;

3) Back insulation of heat treatment furnace;

4) The non-ferrous metal industry deviates from insulation;

5) High-temperature reaction, heating equipment back blood.

Service Content:

1. Respond promptly

Respond to your inquiries in a timely manner, select multiple recommendations according to your needs, quickly reply to emails and provide solutions.

2. Sample evaluation

The quality evaluation can accept the price of fire brick samples and trial orders.

3. Strict quality control

Arrange production more often and strictly control quality.

4. Shorter delivery time.

Book a ship or plane to guarantee delivery time.

5. Professional services

Provide all detailed news and pictures from the order to the delivery; if necessary, provide relevant documents and original certificates; considerate after-sales service.

Pre-sales, during sales, and after-sales services can be enjoyed by dedicated personnel. The above indicators can be referred to. If you have any questions, please contact us and sincerely wait for cooperation!

Regarding What You Want To Ask:

1. Are you a manufacturer or a trading company?

We are a real manufacturer, we can not only provide high-quality products at the most favorable price but also provide the best pre-sales and after-sales services.

2. What kind of products can you provide?

Our company can provide kiln products, such as refractory bricks, refractory castables, and refractory materials.

3. Can your company provide samples or can we visit your factory? Of course, samples are available, and you are welcome to visit our factory at any time.

4. Why did we choose your company’s products?

This is a good question. We are in Yangquan City, Shanxi Province, China, one of the largest refractory bases in the country, so the price and quality of the products can be guaranteed.